Innovating to Thrive for the Next 130 Years

Innovation is not new at Swinerton, it’s one of the reasons our 132-year-old business has spanned across three different centuries. At Swinerton, we have always strived to identify business operations ripe for disruption and identify external disruptors to our businesses.

While many say innovation has been relegated to one of the buzzwords of the decade in business, according to Innovation to the Core: A Blueprint for Transforming the Way Your Company Innovates, companies that set up a successful innovation architecture yielding a competitive advantage are far and few between. The challenge companies face is making innovation happen by creating a blueprint for strategic and industry transformation.

Our innovation architecture was formalized in January 2018 when executive leadership strategically brought in Eric Law, Senior Director of Technology and Innovation, to build Swinerton’s innovation department and program.

As a result, the Swinerton Construction Innovations program is a corporate R&D initiative to ensure Swinerton continues to thrive for the next 130 years. Innovation spans all levels of our business from our processes behind the scenes, which keep our business running, to how we actually build in the field, or even how the buildings we own are operating.

“We focus on changing the people and process, technology is merely an enabler of these changes.”

– Eric Law, Senior Director Technology and Innovation

Innovation at Swinerton Defined

Innovation is about changing how we deliver construction services. The Swinerton program focuses on changing business processes in order to drive substantial reductions in costs while increasing the quality and safety of the work we deliver. We believe the key to transformative solutions is changing the process. Applying technology to existing processes only delivers incremental improvement.

Our main tenets are:

- Execute Innovation Projects: The Innovations team partners with our business users to evaluate, pilot, and deploy new solutions. These projects typically start with the hypothesis: can we reduce cost X% by doing Y? From this hypothesis, we then follow a defined process for evaluating and measuring the solution.

- Drive Innovation Culture: Innovation requires everyone across Swinerton to participate. Innovation cannot be successful in a lab, it has to be validated by the users it will impact. To ensure we have willing users, we have an innovation education program to deliver education training to all new Project Engineers, Superintendents, and Project Managers as well as up-and-coming leaders.

“The Innovation Group has helped foster growth and development of new ideas through Swinerton Mass Timber. One example has been the new fastener tool our crews are using to increase efficiency on the jobsite, making these projects more successful. As an employee-owned company, we take pride in developing new technologies to help create solutions which benefit our team,”

– Chris Evans, Swinerton Mass Timber Director

Examples of Swinerton’s Innovation Projects at Work

Although not the main focus of Swinerton’s Construction Innovation program, technology remains a factor in moving the industry forward. Some of the technology we are working with include:

- Mass Timber Fastening

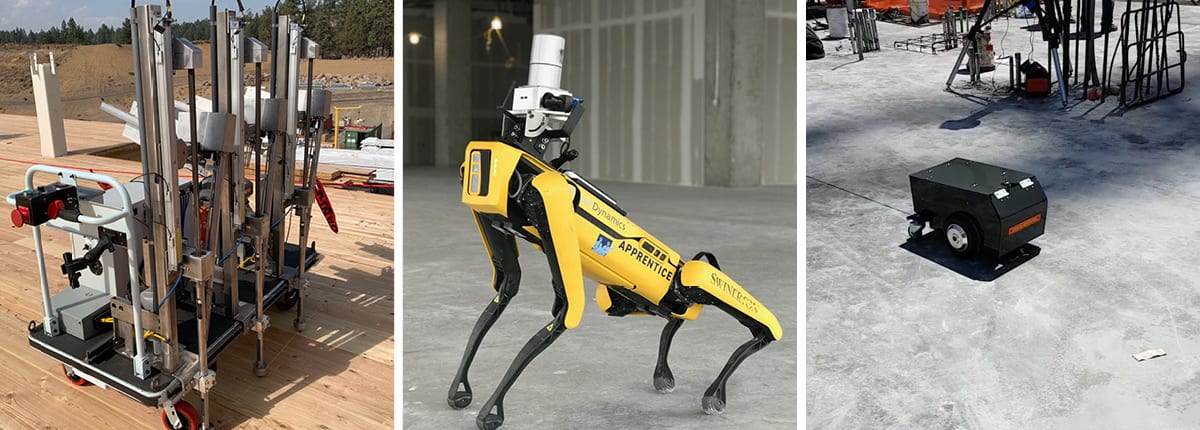

Problem: Fastening Mass Timber decks is labor intensive, hard on the workers, and time consuming. A single project can consume 30,000 screws ranging from 3” to 18” long.

Solution: Create a portable fastening machine to increase productivity and ergonomics.

Benefits: Moves the craft to a standing position greatly reducing the physical impacts of the work. Multiple screws are installed at once, so a single operator can drive screws 50-75% faster. Screws are installed with a push of a button. - Field Data Capture: Spot, Versatile

Problem: Can we use technology to capture the quantity and quality of work put in place? Machines are great at doing the same activity repeatedly, people are not.

Solution: Using cameras and lidar scanning to capture the work put in place combined with the BIM model enable us to progress schedules, conduct cash flow forecasts, generate payment applications, and produce labor productivity reports. - Layout Robot: Dusty Robotics

Problem: Interior wall layout is tedious, requires highly skilled craft, and is hard on craft labor as they must work on the floor drawing points and lines.

Solution: We have partnered with Dusty Robotics, a CA-based startup with a robot that prints lines and characters on the floor using the CAD layout drawings.

“Positively impacting our employees, specifically our craft employees, is at the heart of many of our innovation projects. Being able to spend time in the field with our craft to gather their expert feedback has been an invaluable step in our process. This aids in ensuring ownership of each innovation project is shared across our organization, at all levels.”

– Tristen Magallanes, Innovation Analyst

Innovation that Moves the Industry Forward

Innovation is bigger than Swinerton. While one of the aims of any company’s innovation strategy is differentiation from competition, sometimes it’s to better the industry and society at large.

Moreso than ever before, one of the results of the COVID-19 pandemic is the “Open Innovation” movement where ideas are crowd-sourced, industry best practices are shared, and even unlikely partners join together for speed to market and the greater good.

One such way Swinerton is moving the needle is through joining the NEXT Coalition. With the goal of safeguarding the industry by protecting the lives of our workers and the communities our work impacts from threats including but not limited to COVID-19, NEXT Coalition was devised and created by a coalition of leading U.S. & global engineering and construction firms.

Solution providers submit ideas through the NEXT portal, and each firm reviews and decides if they want to engage with the provider. Currently, the coalition has chosen five pilot projects from 84 proposed applications and products and are vetting 58 more.

“COVID is a new safety risk for the construction industry that requires a rapid, coordinated effort to ensure our employees go home safe every day,” said Law. “Instead of every firm trying to solve the same problem, we can work together to improve safety across our industry. This approach ultimately allows for faster evaluation of new solutions in response to the COVID pandemic.”

Innovation also strives to eliminate waste in a process. Our innovations projects focus on changing and reducing materials and labor from a construction process. Not only does this reduce costs, but it also has the potential to reduce construction’s environmental impact by first reviewing a new process and materials to ensure there is a true benefit. Unfortunately, many prior innovations like plastic have turned into environmental disasters, so we must make sure we do not repeat this mistake.

As we seek new avenues of innovation in our industry, our team strives to create conversation through educating and partnering with external groups. Our education and industry partners include Stanford University’s Center for Integrated Facility Engineering (CIFE), Oregon State University (OSU), and CIDCI, as well as membership with organizations like Women in Innovation. Our team members have participated in roundtable discussions with graduate-level students and take an active role with CIFE, providing students ongoing opportunities for research feedback, experimentation, and internships.